Electrolysis

With the increasing use of renewable energies in industry, mobility and households, energy storage is becoming an important issue.

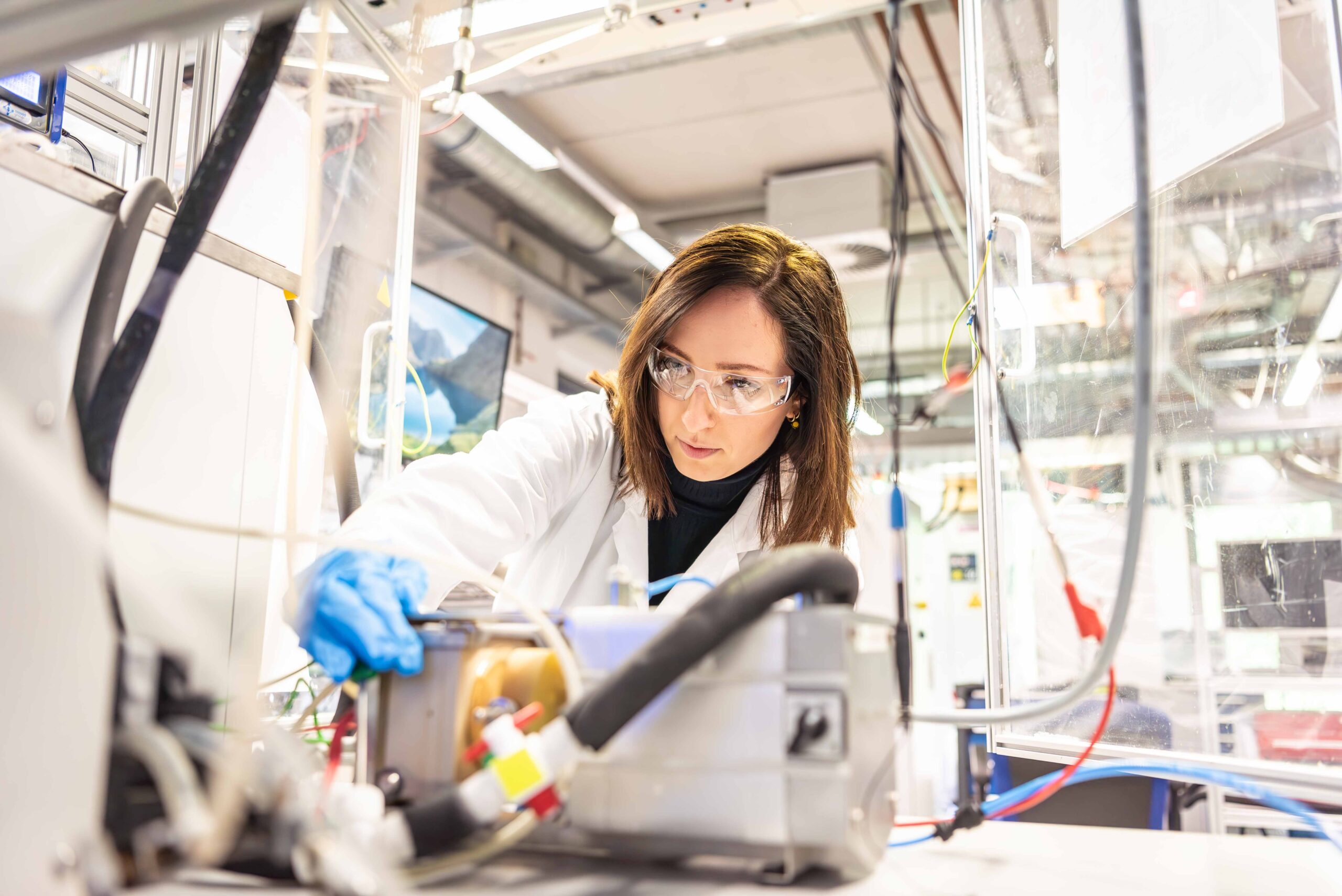

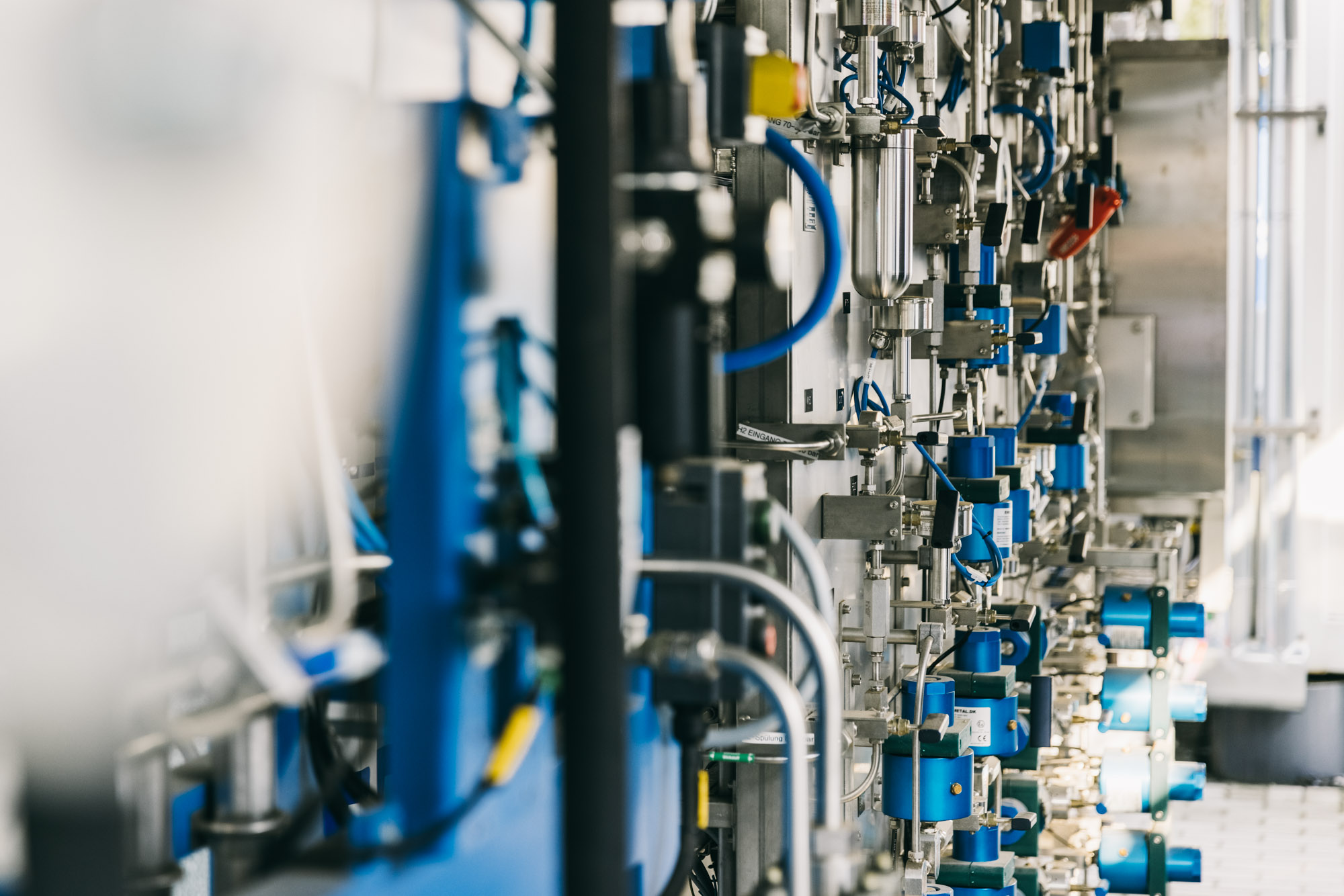

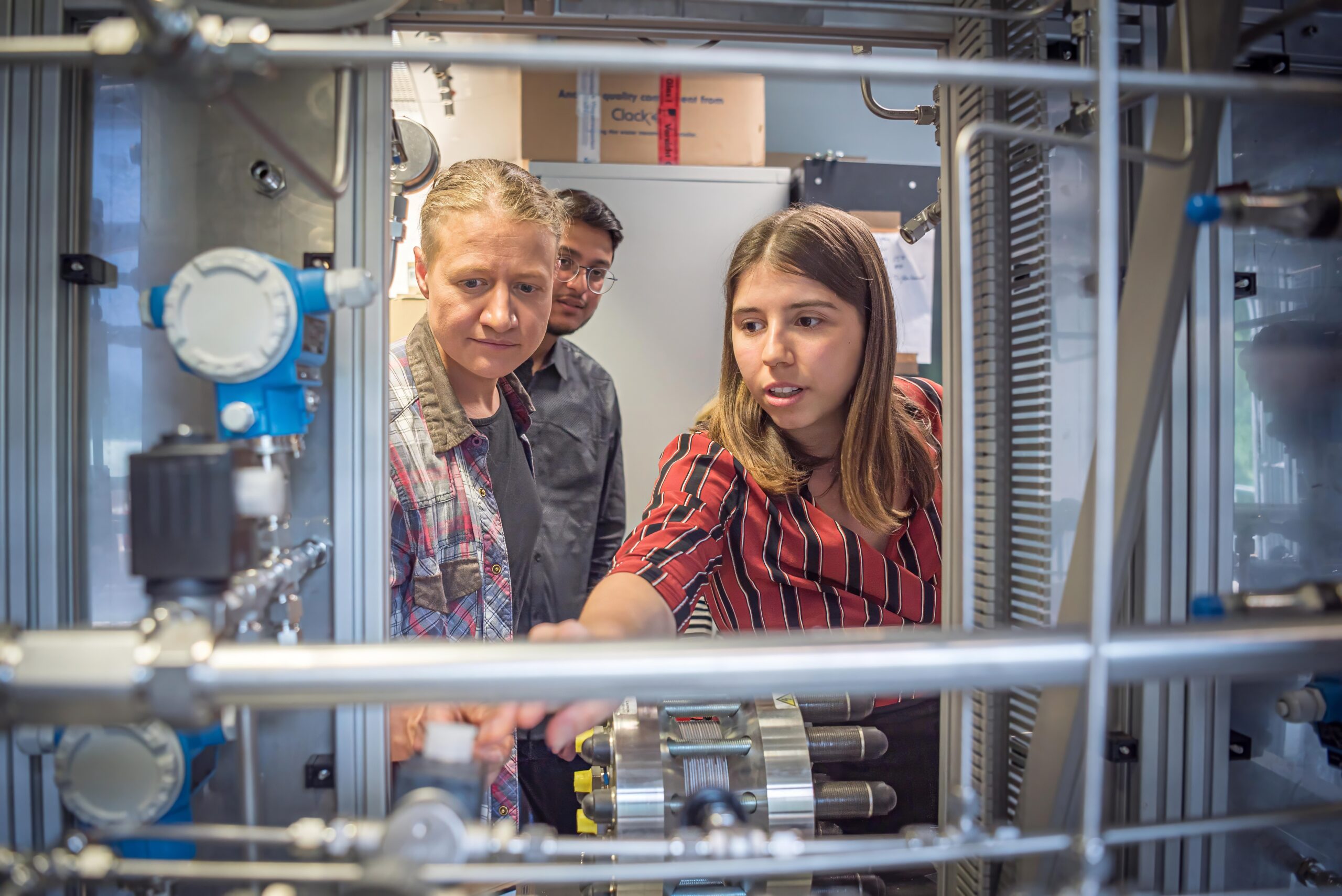

Since electricity from solar or wind energy cannot be used directly in many cases, hydrogen is an important energy carrier for the future design of our energy system. ZBT conducts research in the field of water electrolysis, from component development and the characterisation of materials and components to their testing.

We focus primarily on two electrolysis technologies: AEM electrolysis and PEM electrolysis.