Partner for the Development of Hydrogen Technologies

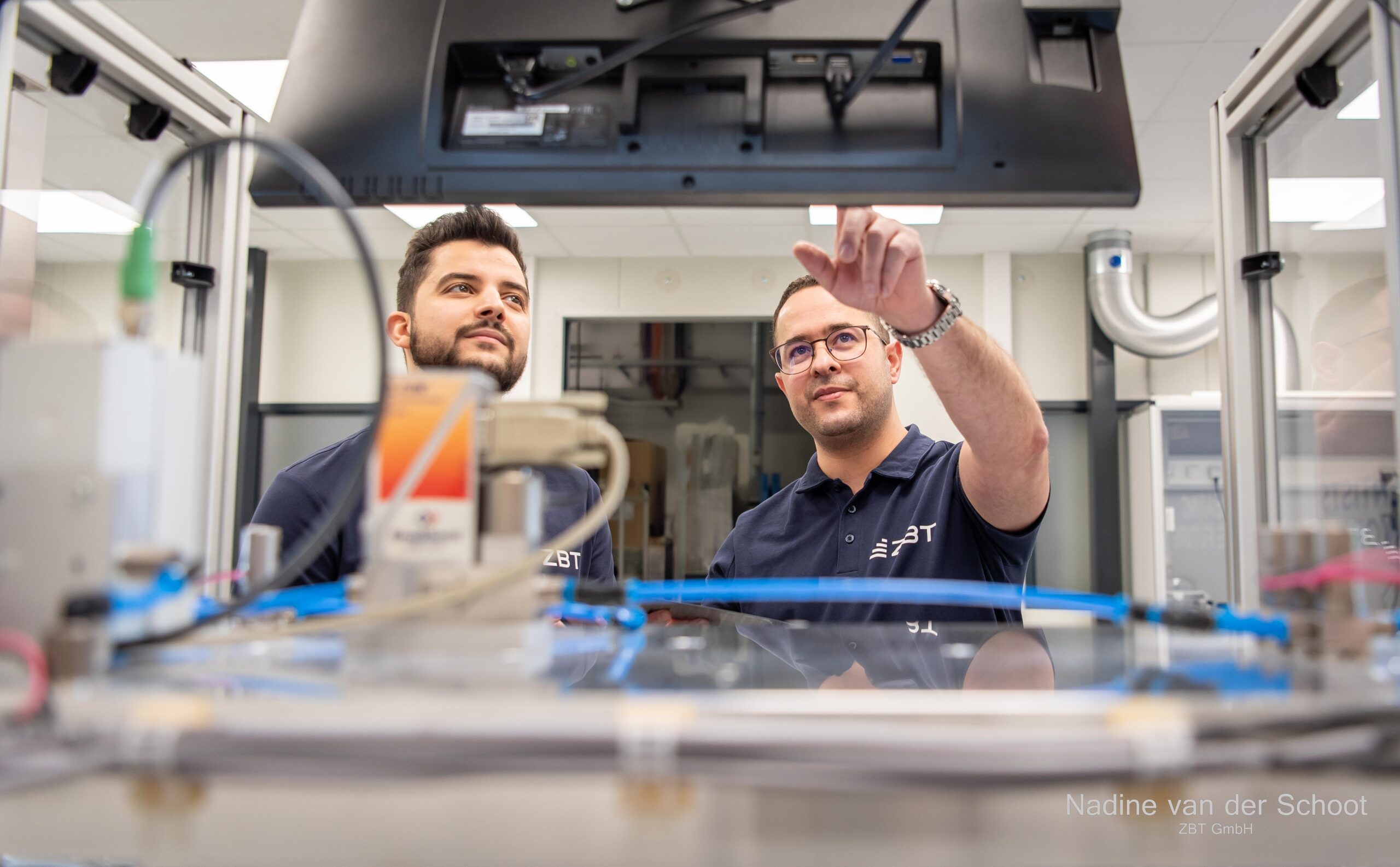

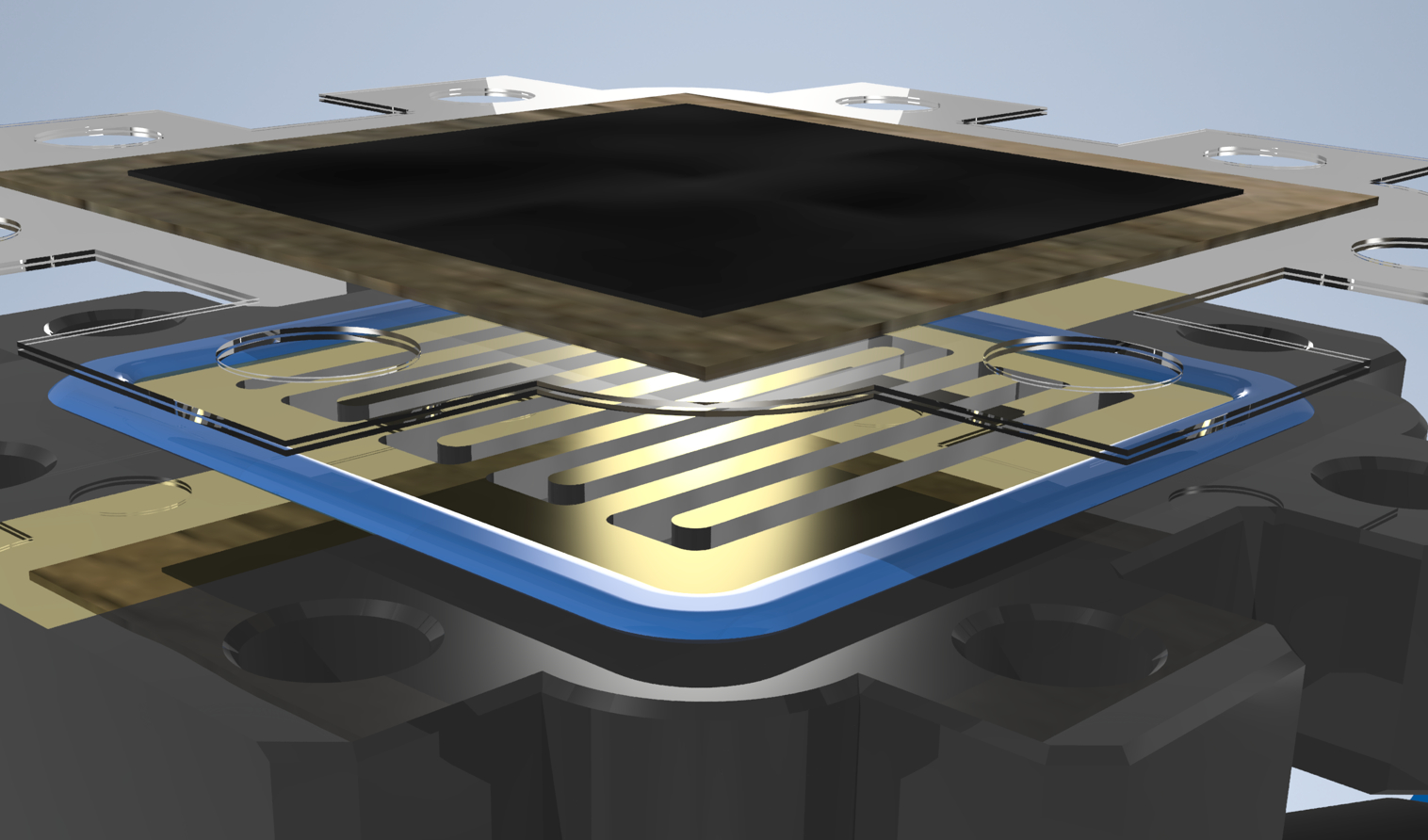

Fuel cells, electrolysis, hydrogen storage and refuelling, ammonia technologies and much more – from the nano to the system level. ZBT supports industry and research with a wide range of services.

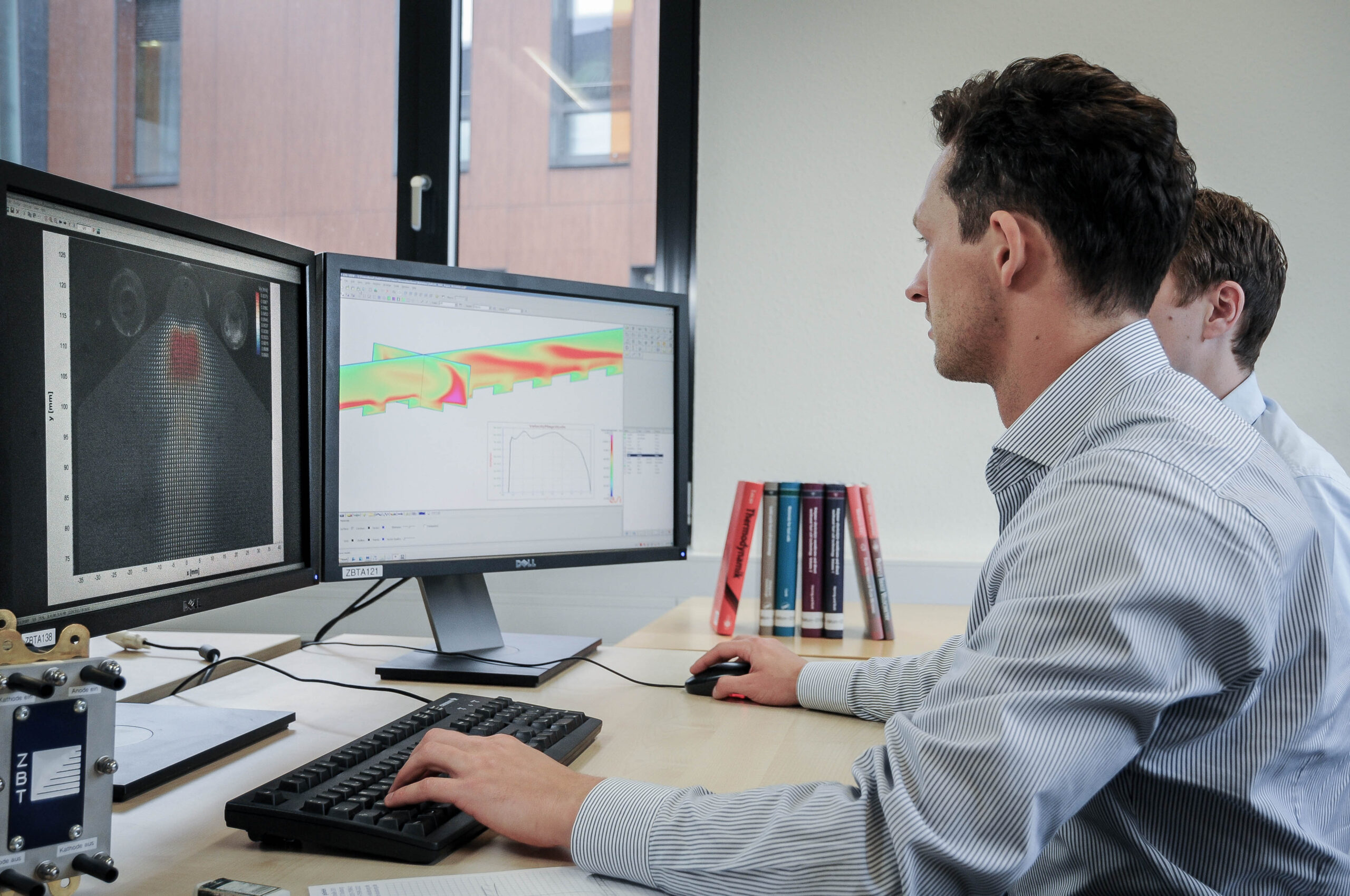

We actively support the development departments of companies and research institutions with our expertise: you can book our services in analytics, material characterisation, testing and qualification procedures, and technical consulting.

The range of services is complemented by exclusive contract research and publicly funded projects. This allows us to seamlessly integrate scientific excellence with application-oriented implementation throughout the entire development cycle of hydrogen technologies.

Services provided by the ZBT

ZBT offers customers from research and industry a wide range of services in four areas: development services, production processes, measurement and testing services, and consulting and studies. In R&D projects, we use all our expertise to provide our industrial partners with the best possible support. We also test and inspect new developments – neutrally and independently. If you have any questions about technology, infrastructure or production relating to fuel cells, hydrogen and electrolysis, we are happy to provide advice and assistance.

Equipment

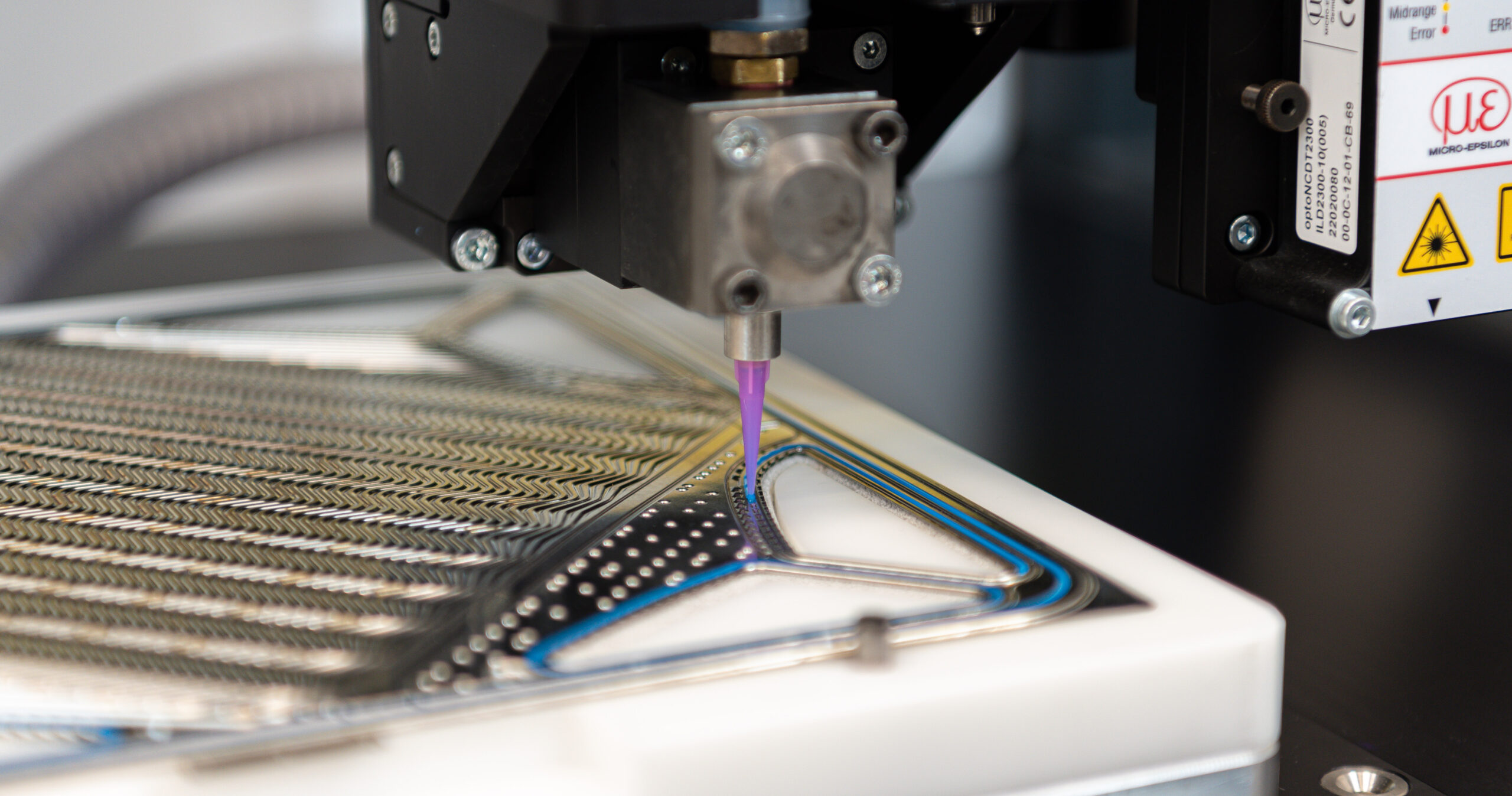

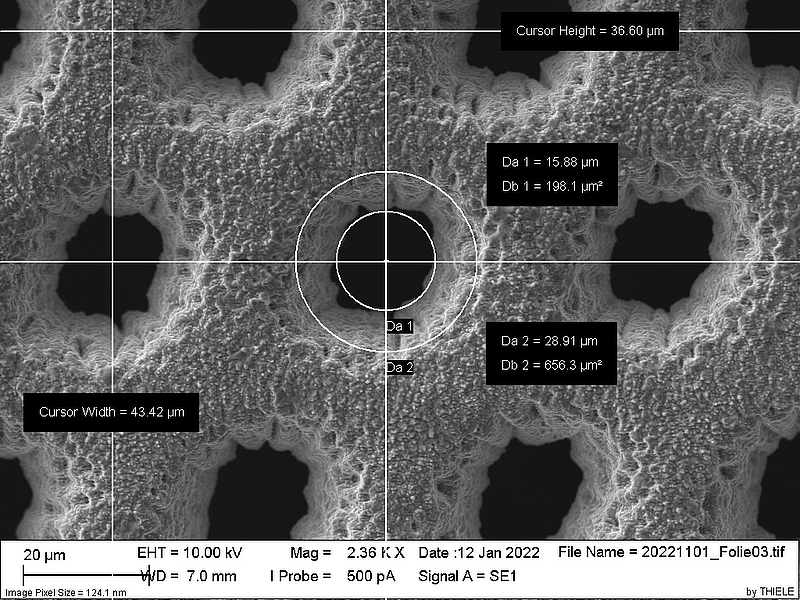

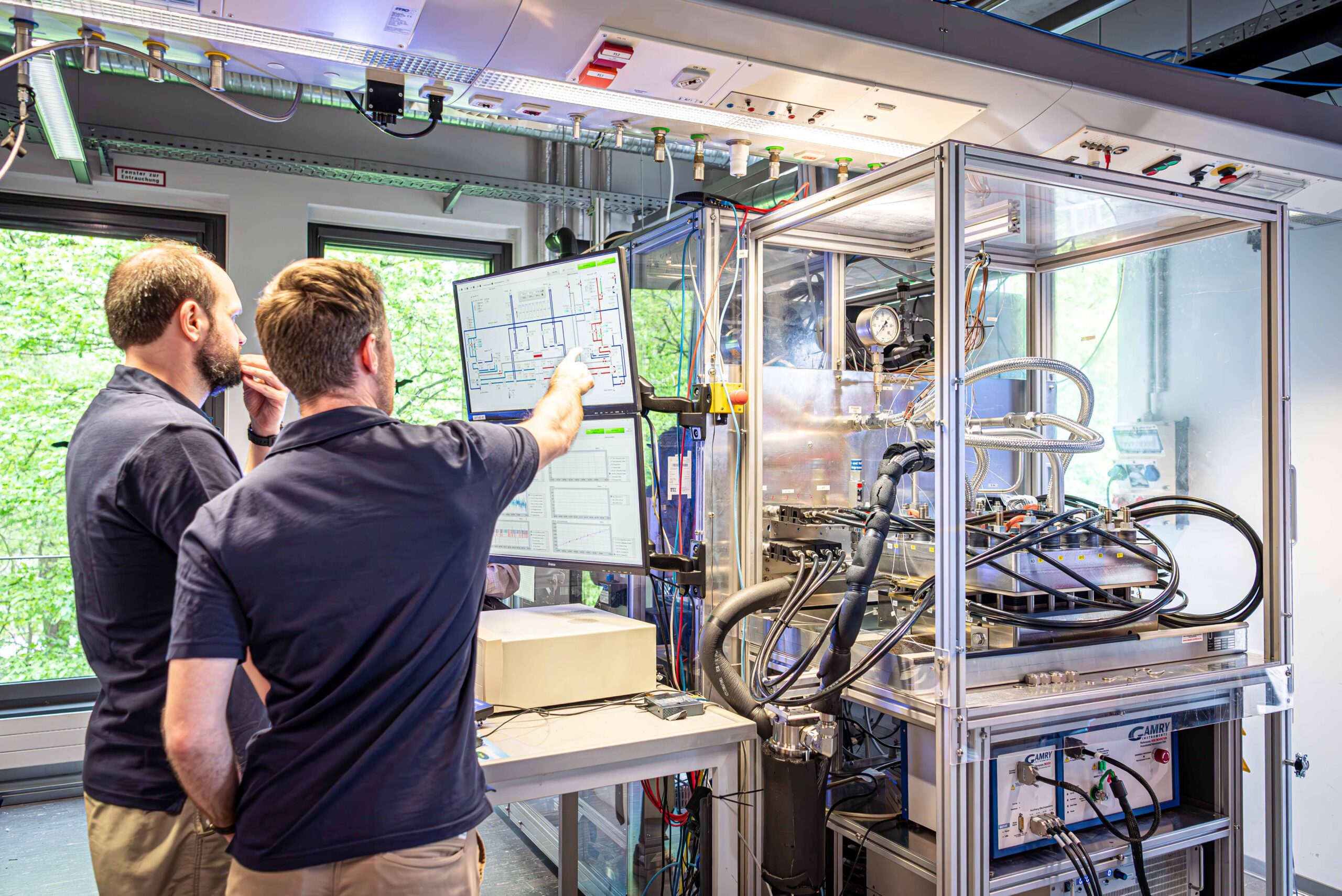

The ZBT has everything you need for cutting-edge research in the field of hydrogen and fuel cells. We have high-end laboratories, wet chemistry facilities, a wide range of measuring instruments and a large number of commercial and custom-developed test benches and production facilities.

Our hydrogen quality laboratory, Hy-Lab, is one of only two laboratories of its kind in Germany. There, we determine the purity of hydrogen samples and analyse contaminants.

At our hydrogen test field, we can examine the interaction of systems and components of a hydrogen infrastructure on a 1:1 scale.