Development

From the initial material idea to system maturity – integrated development approaches for electrochemical technologies

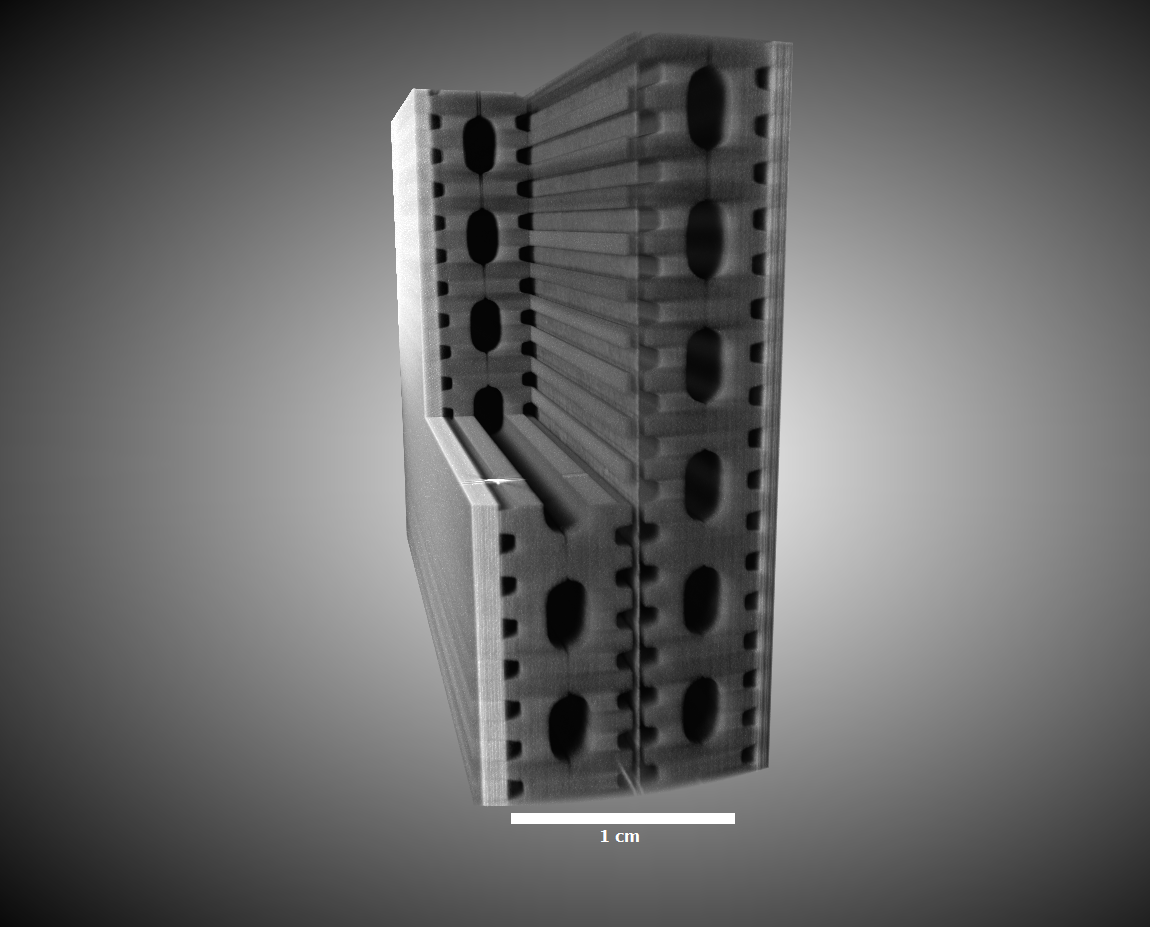

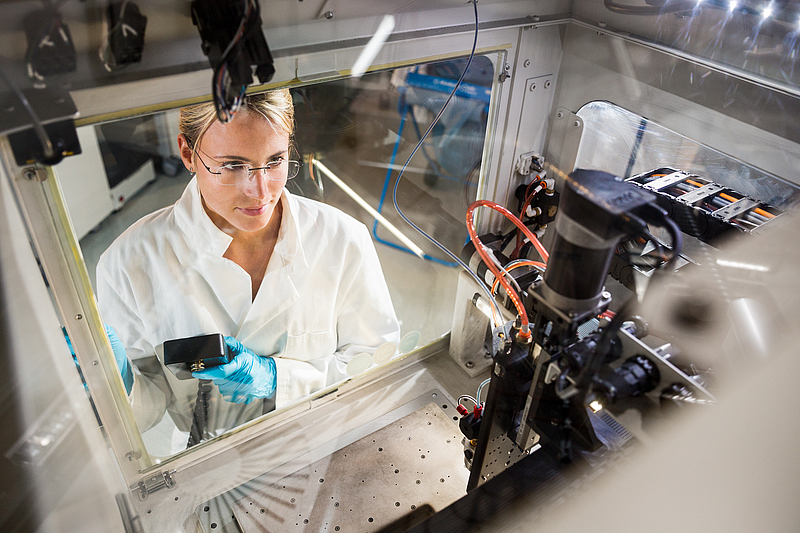

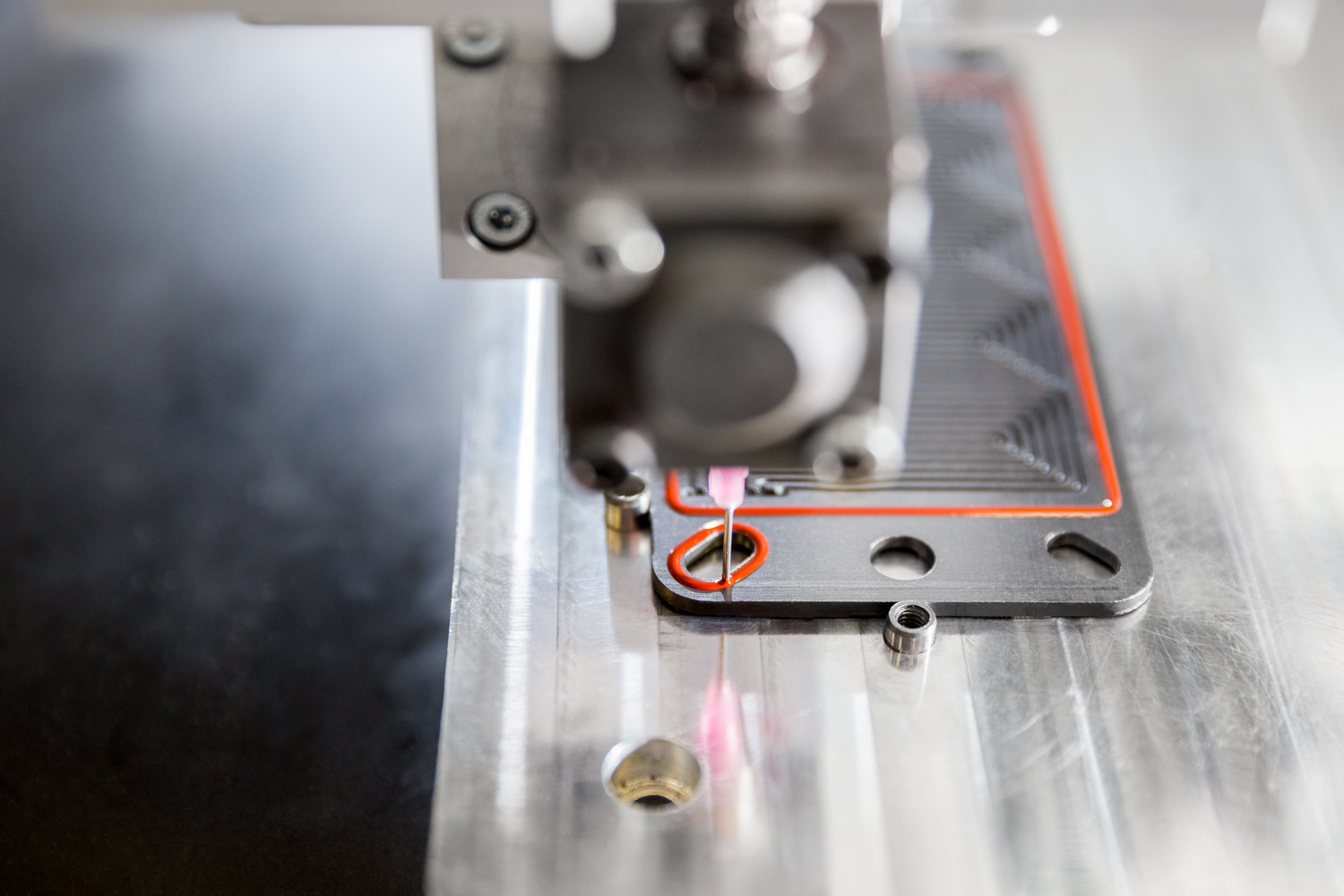

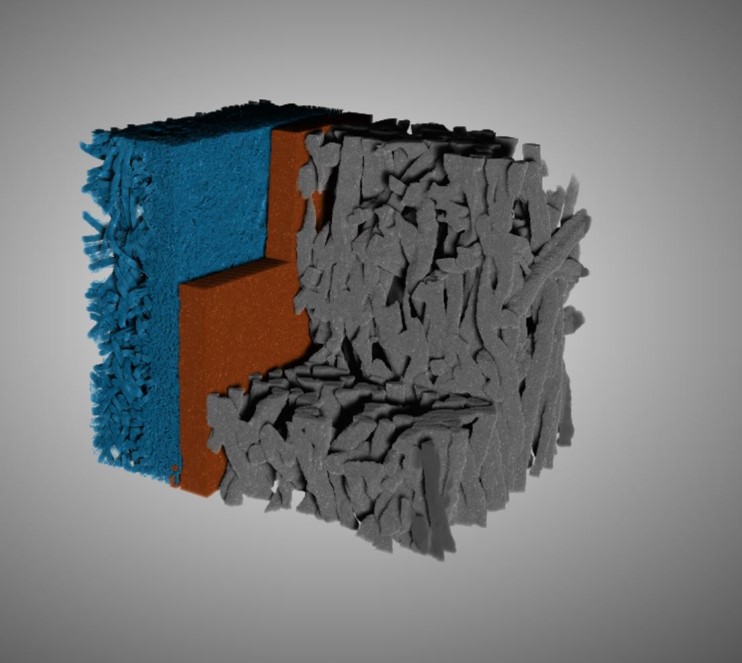

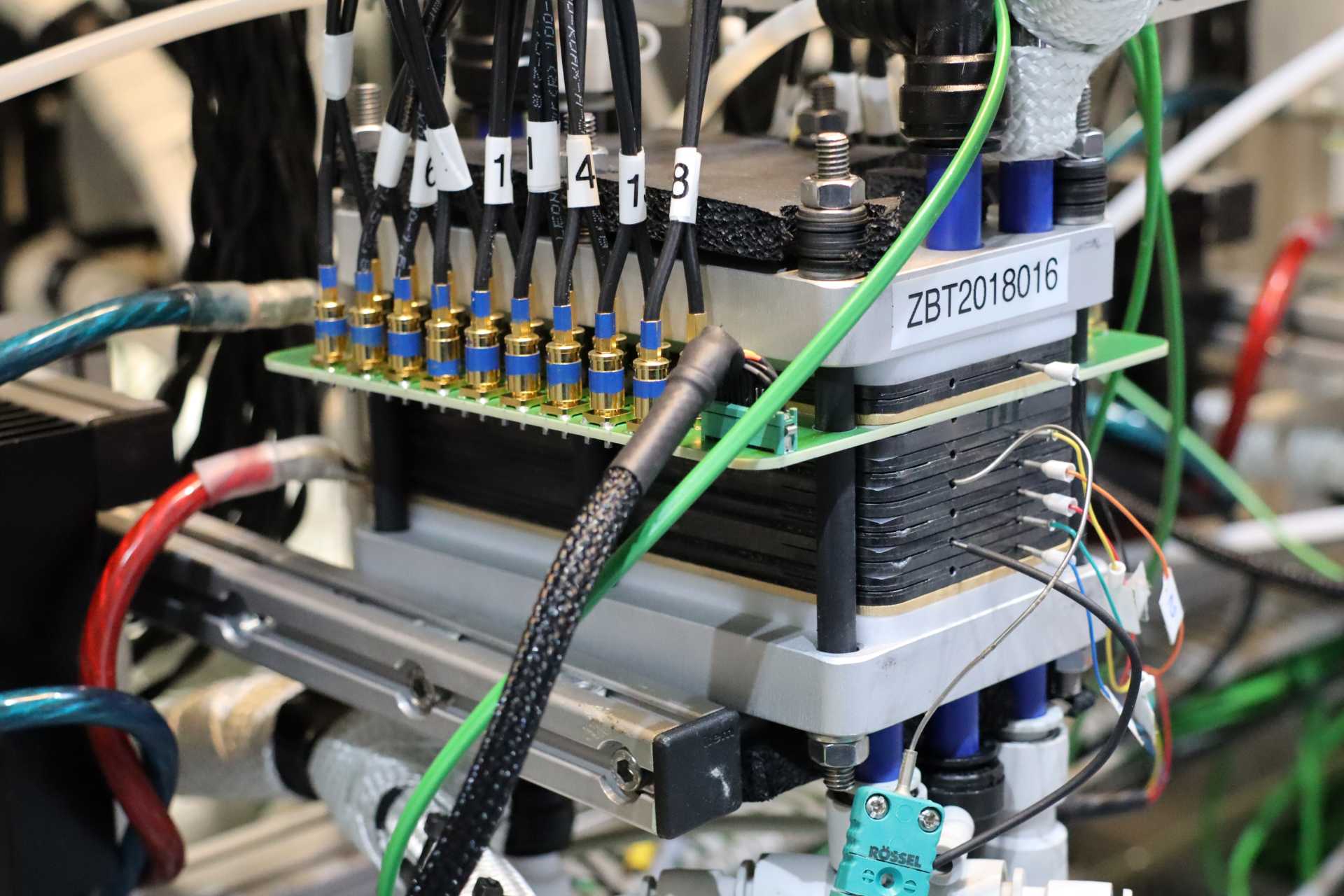

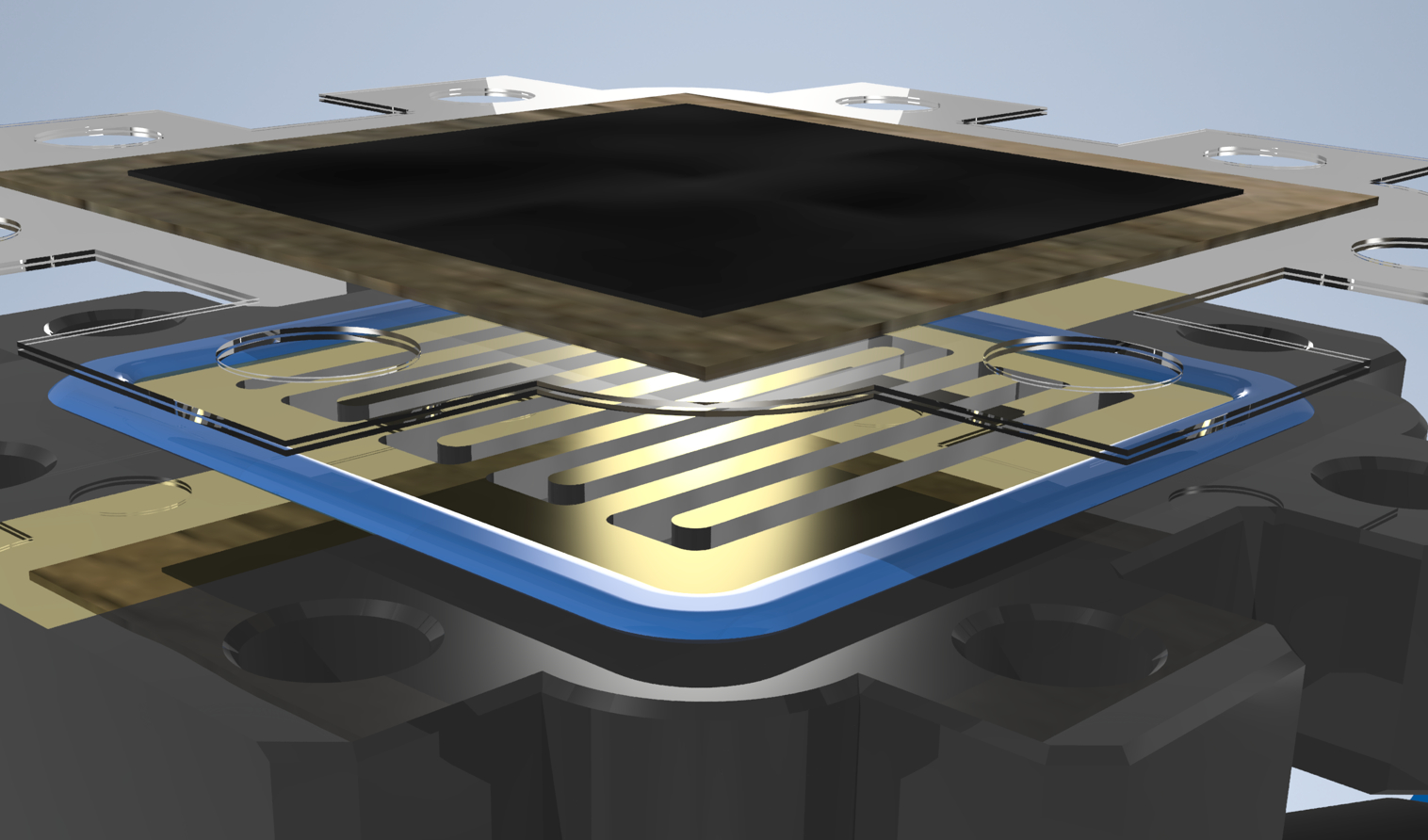

Development work at the ZBT includes the systematic design, material development and operating strategy of electrochemical components. The aim is to optimise fuel cell and electrolysis systems for specific applications along their entire value chain – using established CAD tools, laboratory-based materials research and simulation-based control concepts.